A bearing cage is one of the essential components of any bearings. Its function is to grab rolling elements in the proper orientation to prevent them from grouping together. Bearing cages are manufactured using different materials and with various manufacturing processes. To select the right product to meet your need, you need to connect with a popular and reliable bearing cage supplier

However, we are highlighting some of the points that need to be considered before selecting a bearing cage.

Steel Vs Brass Cage

Many studies have found that the high-tensile brass cages are better than their steel counterparts. Brass cages offer many benefits over steel cages, aluminum, and other non-metallic bearing cages. Also, brass cages have the quality of ensuring high strength, and high rigidity, and can be used at high temperatures. So, it is better to go for a brass cage.

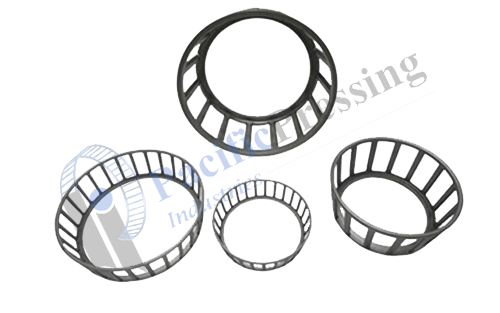

Types of Bearing Cage

Crown and ribbon are two types of bearing cages in rotary bearings.

- Crown cage: This cage is a single-piece, open ball pocket design.

- Ribbon Cage: This type of cage is designed to have a two-piece open ball pocket design.

Refer to the bearing cage supplier in order to choose the correct bearing separators to adhere to your particular application.

Features and Specifications of Bearing Cage

When selecting a bearing cage, looking at the features and specifications of the bearing case is very important. Even minor changes in design, size, and the feature will fail to meet your requirements. So, when choosing a cage, do consider the loads and speeds of application, acceleration issues, and environmental conditions, like contamination and temperature. Moreover, you also need to consider the high-speed running, vibration levels, and requirements for lubrication. Always consider these points before buying bearing cages.

Materials of Bearing Cage

The next step is to look at the materials of the cage. Usually, these bearing cages are made of brass, steel, solid bronze, heat-treated aluminum, or pressed steel. In addition, there are some non-metal like phenolic resigns, and nylon that are used to manufacture bearing cages. As mentioned above, brass cages come with the best characteristic features and can function well even in corrosive and harsh environments. However, the materials of bearings depend on the applications where these bearing cages are used. So, choose one depending on the specific application requirements.

Conclusion

It is worth noting one size doesn’t fit all. Bearing cages cannot be suitable for every application. To take an example, there is no requirement for a full-complement bearing with cages in applications with high loads and low speeds. It is therefore important to explain your requirements to the bearing cage supplier who will help you select the right retainer.